How Open Mouth Bagging Machines Lower Costs Across Multiple Industries

As industries continue to grow and innovate, businesses are constantly looking for ways to streamline processes, reduce costs, and maintain product quality. One such game-changing solution in packaging is the open mouth bagging machine. These machines combine speed, precision, and automation, making them cost-efficient packaging solutions for industries like agriculture, chemicals, construction, and food processing.

What Are Open Mouth Bagging Machines?

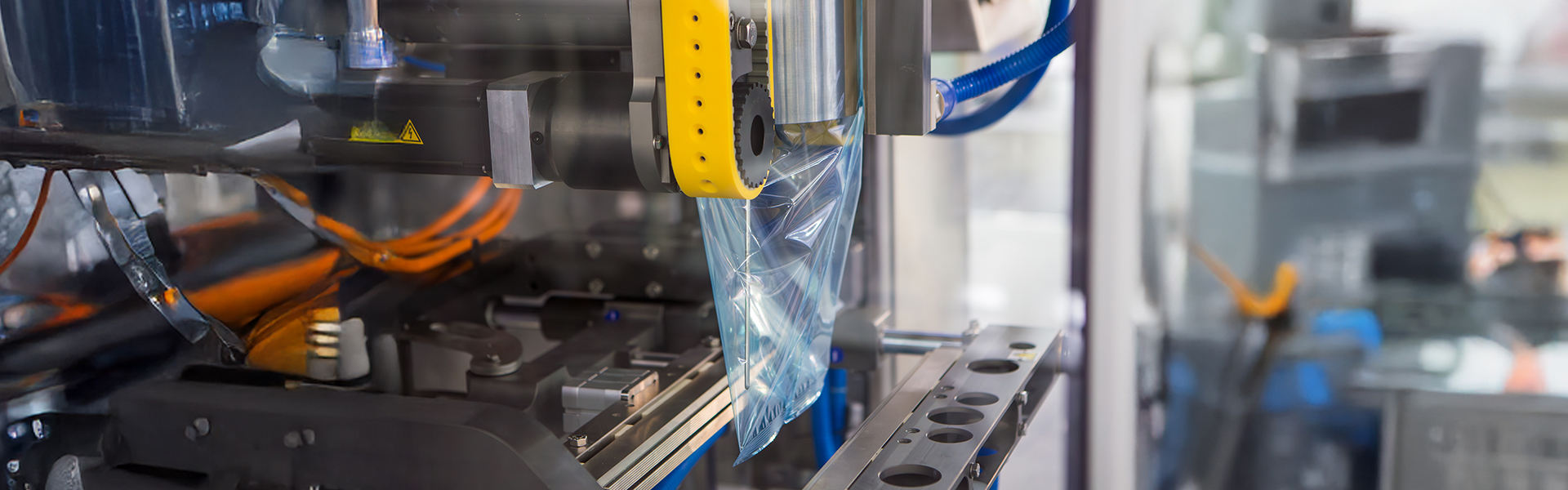

Open mouth bagging machines are specialized equipment used for packaging bulk products like seeds, grains and pulses, powders, fertilizers & granules into pre-formed bags. The process involves placing an empty bag under a filling spout, where the material is weighed and dispensed. Once filled, the bag moves to a conveyor for sewing or sealing.

Key Features of Open Mouth Bagging Machines

- Flexible Bag Handling: Easily switches between different types of bags.

- Advanced Sensors: Provides real-time data monitoring for accuracy.

- Safety Standards: Compliance with global safety requirements.

- User-Friendly Design: Easy to operate, even for beginners.

- Smart Adjustments: Automatically adapt to different packaging needs.

- Intelligent Filling System: Ensures precise material handling.

- Custom Configurations: Can be tailored to specific industry requirements.

How Open Mouth Bagging Machines Lower Costs

- Cost-Efficient Packaging Solutions:

Open mouth bagging machines ensure precise weighing and filling, preventing overfilling or underfilling. This presents you with an accurate filling and weighing systems, and minimizing packaging errors. - Bagging Machine Automation Benefits:

With automation features, open mouth bagging machines significantly reduce manual labour. Thus, minimizing packaging errors, streamlining operations leads to substantial cost-saving in material handling. - Reduced Labor Costs in Packaging:

Traditional manual bagging methods require a lot of manpower. In contrast, automated bagging systems perform tasks like cutting, stitching, and sealing efficiently with fewer workers, offering reduced labor costs in packaging. - High-Speed Bagging Technology:

Open mouth bagging machines by Alligator Automations can process up to 20 bags per minute, ensuring fast, reliable, and high-volume operations. This reduces production delays and ensures timely delivery, saving costs. - Minimizing Packaging Errors:

Errors in packaging can lead to significant losses due to rework or product rejection. The accurate filling and weighing systems in these machines minimize such errors, ensuring consistent packaging quality and enhancing brand reputation.

Applications Across Industries

Open mouth bagging machines are versatile and used in multiple sectors:

- Agriculture: Packaging seeds, grains, and pulses.

- Chemicals: Handling fertilizers, powders, and granules.

- Construction: Bagging cement and other materials.

- Food Processing: Packaging items like sugar, flour, and spices.

Open mouth bagging machines are compatible with various bag types, including polywoven, LDPE, HDPE, and paper bags, offering unmatched flexibility.

Why Choose Alligator Automations for Packaging Solutions?

Alligator Automations is a leader in innovative packaging automation solutions, providing cutting-edge systems tailored to industry needs. Our open mouth filling systems stand out with:

- Advanced IoT-enabled features.

- Compliance with international safety standards.

- Fully or semi-automated options to suit diverse operational requirements.

By incorporating machine learning in packaging processes, Alligator Automations delivers unparalleled accuracy, reliability, and cost-effectiveness to our clients.

Conclusion

Incorporating open mouth bagging machines into your operations is a game-changer. From reducing labor costs to enhancing accuracy and speed, these machines help industries achieve long-term profitability. For businesses seeking cutting-edge solutions in packaging automation, Alligator Automations is the trusted partner offering superior systems that deliver measurable results.

Take the first step towards cost-efficient packaging. Explore Alligator Automations’ Open Mouth Bagging Machines today!

FAQs

- How do Open Mouth Bagging Machines help in reducing labor costs?

By automating tasks like bag placing, filling, and sealing, they minimize manual intervention, significantly cutting labor costs. - What industries benefit from cost savings by using Open Mouth Bagging Machines?

Industries like agriculture, chemicals, construction, and food processing benefit from reduced packaging costs. - Can Open Mouth Bagging Machines improve packaging speed?

Yes, they achieve speeds of up to 20 bags per minute, enhancing productivity and reducing delays. - Do Open Mouth Bagging Machines affect the quality of packaging?

Yes, they ensure accurate filling and consistent sealing, improving packaging quality. Alligator Automations offers advanced solutions tailored to ensure precision and efficiency in packaging processes.