How Robotics are Transforming Palletizing Systems in Manufacturing

The use of robotic palletizing systems is reforming the manufacturing industry. While traditional palletizing relied heavily on manual labor, making it repetitive and ergonomically risky, robotic palletizers have brought about significant improvements in efficiency, productivity, and workplace safety. Automated palletizing solutions help businesses address labor shortages, boost efficiency, and ensure safer operations.

Benefits of Robotic Palletizing:

- Speed and Precision –

Robotic palletizing systems ensure faster and more accurate stacking. They ensure uniform stacking patterns, reducing errors and enhancing the quality of stacked goods. High-speed robotic palletizers are capable of handling multiple product types simultaneously, making them ideal for high-demand environments. - Flexibility and Adaptability –

Modern robotic palletizers can manage various packaging formats, sizes, SKUs, and payloads. Features like adaptive grippers and vision systems minimize the need for moulds or manual adjustments, reducing downtime and improving overall efficiency. - Improved Safety and Ergonomics –

Robots eliminate the need for manual labor in hazardous palletizing tasks, protecting workers from injuries and ensuring safer operations. These systems also support ergonomic improvements, promoting better occupational health. - Cost Efficiency –

The integration of robotics reduces reliance on manual labor, leading to significant cost savings. The benefits of robotic palletizing also include minimized product damage, optimized space usage, and error reduction, which translate to enhanced operational profitability.

Features of Advanced Palletizing Systems:

Alligator Automations’ palletizing systems come with advanced features like:

- Easy Programming: Seamless transitions between different products.

- Slip Sheet Automation: Adds stability and weight to stacks.

- ERP Integration: Full compatibility with plant management systems.

- IoT Connectivity: Real-time monitoring and control of activities.

- Flexible Stacking: Enables complex and customized stacking designs.

Types of Palletizing Systems by Alligator Automations:

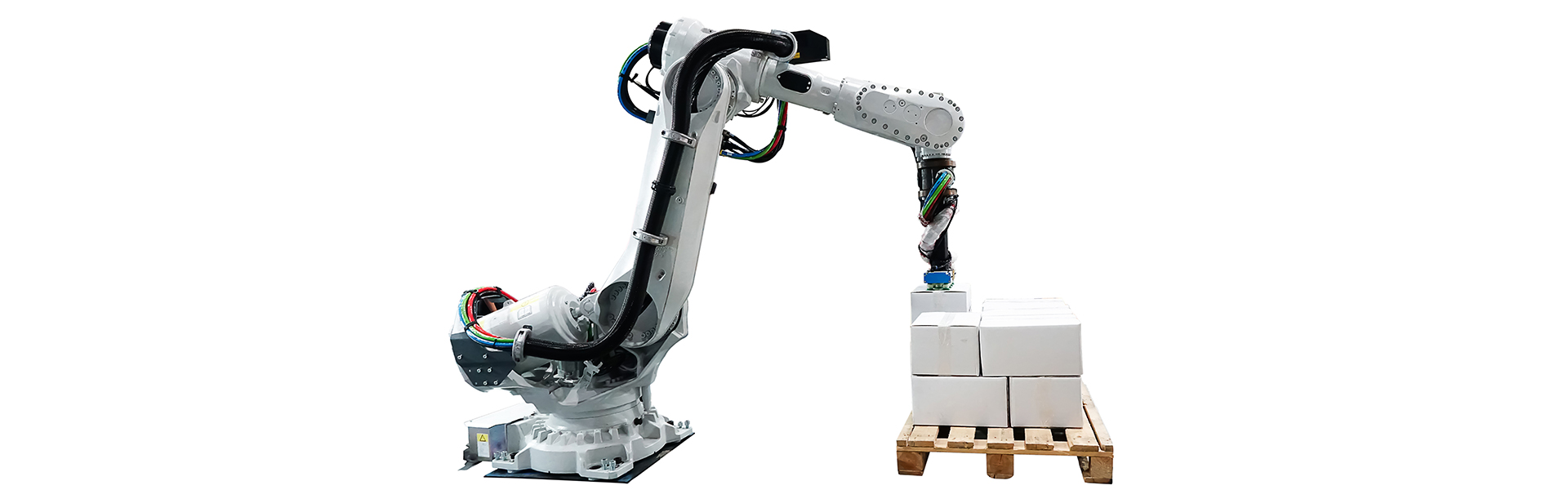

- Robotic Palletizing: High-speed, precise handling in various layouts.

- Gantry Palletizing: Multi-axis systems for accurate stacking.

- High-Level Palletizing: Reliable vertical stacking solutions.

- Low-Level Palletizing: Efficient infeed and orientation processes.

- Hybrid Palletizing: Combines robotic precision with speed and compact design

Why Manufacturers Are Switching to Robotic Palletizing:

- Reduced Labor Costs: Automation handles repetitive tasks, lowering dependence on manual labor.

- Operational Efficiency: Faster cycle times improve output and productivity.

- Improved Hygiene: Robots maintain higher sanitation levels.

- Error Reduction: Smart systems minimize stacking mistakes, ensuring consistent quality.

Why Choose Alligator Automations for Palletizing Systems?

As a leader in advanced palletizing systems, Alligator Automations offers cutting-edge solutions tailored for high performance and flexibility. Our solutions — including high-speed robotic palletizers and hybrid systems — transform the way products are packed, stacked, stored, and shipped.

Conclusion

Robotic palletizing systems are no longer optional—it’s essential for manufacturers aiming to stay competitive. Alligator Automations provides customized solutions to improve productivity, safety, and cost efficiency. Whether you need robotic palletizers, gantry, or hybrid palletizing systems, Alligator Automations ensures your operations achieve unmatched flexibility and performance.

Future-proof your packaging with Alligator Automations! Transform your processes and boost efficiency today!

FAQs

- How do robotic palletizers work in manufacturing?

Robotic palletizers use advanced programming, vision systems, and adaptive grippers to stack products like boxes and bags onto pallets with precision and speed. - What are the benefits of using robotics in palletizing systems?

Robotics in palletizing systems improve efficiency, reduce labor costs, enhance safety, minimize errors, and handle complex stacking patterns. Alligator Automations offers tailored solutions for these benefits. - Can robotic palletizers handle different types of products?

Yes, robotic palletizers handle diverse products like bags, drums, and shrink packs using adaptive tooling and advanced controls. - What role does AI play in robotic palletizing?

AI enables robotic palletizers to optimize stacking patterns, adapt to product variations, and ensure seamless integration with ERP systems. Alligator Automations incorporates AI for smarter palletizing operations.