Gantry Palletizing

Gantry Palletizing Machine Manufacturer in USA

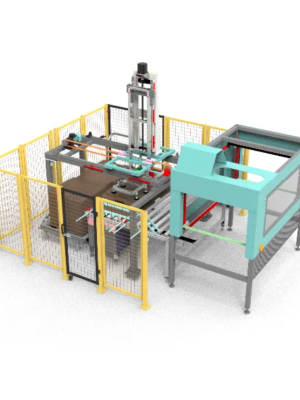

The Multi-Axis Gantry system picks up products from an infeed conveyor and places them in a specific pattern on pallets. It’s a cost-effective alternative to multi-axis robot palletizing.

Our Gantry Palletizer handles heavy products with precision and speed. It’s designed to work with multiple inputs and outputs at controlled speeds, managing up to four placements per minute. This flexibility allows it to handle different container sizes with ease. It also enables easy removal of full pallets, either manually or automatically, with various conveyor or shuttle options.

Precision • Innovation • Efficiency

Industry Leaders in Packaging Automation – Our Impact

Specifications

Type

Product size range

100mm – 1000mm L

100mm – 1000mm W

50mm – 500mm H

Payload

5Kg – 500Kg

Speed

Layout type

Customizable

Product to be handled

Bags, cases, bottles, shrink packs, paint buckets, drums, totes, etc

Features

- Compact footprint effectively uses limited floor space

- Capable of depalletizing full layers

- Designed for easy expansion to accommodate future palletizing requirements

- Rugged heavy-duty design

- A sturdy frame constructed from heavy-duty structural tubes

- A robust rack and pinion system ensures accurate motion and positioning

- Clean design with capped and sealed tubes

- Smooth and quiet operation

- High-speed and high-capacity options enabled by gear motor drive

- Precision infeed with blade-stop positioning for positive drive

- Operates through electro-pneumatic mechanisms

- User-friendly HMI

- 4 servo axis of motion

Add Ons

- Online dynamic check weigher available on request

- Metal detection available on request

Revolutionary • Intelligent • Future-Ready

Our Automatic Bagging Machines, Systems & Solutions

Robotic Palletizing

High Level Palletizing

Our High-Level Push-Type Palletizer is sturdy, featuring a vertical frame that moves along a strong structure to support the pallet being built. An orienting device correctly positions bags from the filling line. They’re then arranged on a conveyor according to a set pattern, and each completed row moves to a holding area.

When a layer is finished, a pusher moves it over trapdoors that drop it onto the pallet, compacting it tightly. Then, the doors open to place the layer on the pallet, and the frame lowers to start the next layer.

Low Level Palletizing

We specialize in Low-Level Palletizing. Here’s the premise behind the system—products on the infeed conveyor are rotated for correct orientation before reaching the row formation area. Completed rows are then pushed onto a layer-forming area, which might be a table, depending on the machine’s design.

The fully formed layer advances to a plate and is either lowered or raised to align with the stationary pallet or previous layer. The process repeats until the palletization is complete. Finished pallets move to the elevated pallet discharge conveyor.

Hybrid Palletizing

A hybrid palletizer combines a robotic system with a high-level palletizer that has a compactor. In the setup, the robot carefully arranges a layer of products on a compactor table. Once the complete layer is moved onto the pallet for stable stacking.

The system is particularly effective for stacking bags, ensuring they’re arranged securely through compaction. The upside of the hybrid palletizer lies in its flexibility. It can handle a wide variety of products and can easily adjust to different palletizing patterns.

Trusted by Industry Leaders Worldwide

Meet Our Valued Clients

Get In Touch

Have questions or need a customized automation solution? We’re here to help! Reach out to us for expert guidance, tailored solutions, and seamless support. Whether it’s inquiries, collaborations, or service requests, our team is ready to assist you. Contact us via phone, email, or visit our office—let’s drive efficiency and innovation together!