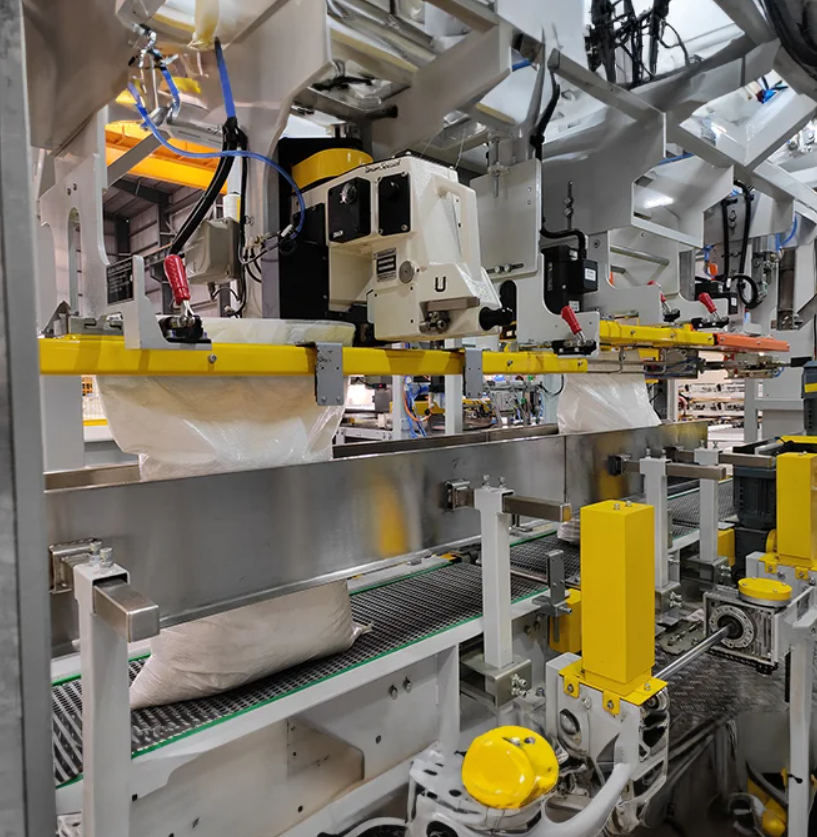

Open-Mouth Filling Systems

Open-Mouth Filling Machines Manufacturer in Australia

Open-Mouth Filling Systems are used to package a wide range of materials and bulk products. In this process, an empty bag is placed under the fill spout and on a weighing scale. Once filled, the bag is released and falls onto the sewing conveyor belt.

Precision • Innovation • Efficiency

Industry Leaders in Packaging Automation – Our Impact

Specifications

Operation mode

Automatic (bag placing and sewing fully automated)

Semi-automatic (manual placing and feed to sewing)

Type of feeder

Belt, screw, vibratory & gravity

Type of weighing

Net weigher/gross weigher

Suitable for

Seeds, grains & pulses

Powders, fertilizers & granules

Suitable bag type

Polywoven bag

LDPE

HDPE

Paper bag

Packaging method/ Bag closing type

Sealing

Stitching

Bagging speeds

Upto 20 bags/min (depends on the product)

Bag feeding system

Magazine feeder

Bag width

250 – 650 mm

Bag length

500 – 1200 mm

Type of sealing

Thread stitching/heat sealing

Filling/weight

10-50 kg

MOC

SS/MS (as per product requirements)

Features

- Highly versatile (quick bag changeover)

- Data logging and IoT-enabled system

- Comply with all international safety regulations

- Ergonomic design

- Fully automatic adjustment

- Smart filling system

- Easy to operate with minimum effor

- Low operator skills required

- Customizable as per user site requirements

Add Ons

- Bag kicker

- Bag flattener

- Inline check weigher

- Inline metal detector

- Automatic rejection

- Stainless steel version available on request

Revolutionary • Intelligent • Future-Ready

Our Automatic Bagging Machines, Systems & Solutions

FIBC Jumbo Bags

We offer a versatile range of Bulk Bag Fillers, available in semi-automatic and fully automatic options, with capacities ranging from 500kg to 2000kg. Suitable for various project scales and budgets, our Bulk Bag Fillers precisely package dry granular, flakes, or powdered materials. The Bottom Vibration arrangement enhances material compaction during filling, guaranteeing superior product quality.

Trusted by Industry Leaders Worldwide

Meet Our Valued Clients

Get In Touch

Have questions or need a customized automation solution? We’re here to help! Reach out to us for expert guidance, tailored solutions, and seamless support. Whether it’s inquiries, collaborations, or service requests, our team is ready to assist you. Contact us via phone, email, or visit our office—let’s drive efficiency and innovation together!