Tire Handling Solutions

Tire Handling Conveyors Manufacturer in Australia

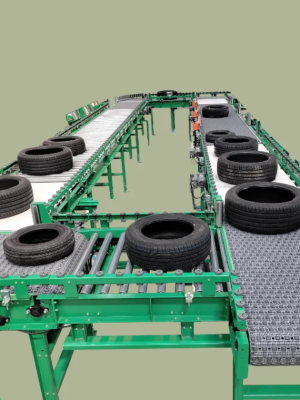

Optimize your tire and wheel manufacturing processes with our conveyor systems. Designed to transport everything from raw materials to finished tires, our conveyors ensure efficient movement while minimizing risk and waste. We offer solutions that include specialized conveyors with protective coatings and precise control programming for optimal product handling.

Precision • Innovation • Efficiency

Industry Leaders in Packaging Automation – Our Impact

Specifications

Conveyor Type

Load Capacity

440 lbs (Customizable)

Speed (m/min)

10-50m/min

Type of Tires

2 Wheeler, PCR & TBR Tires

Sorting System

Belt material

Features

- Space saving, efficient storage

- Ergonomic tire & wheel handling

- Accurate and secure product transport

- Speed up tire handling up to and down from your mezzanine at a pace as fast as 12 tires per minute

- Tough enough for all your tire/wheel assemblies—heavy-duty belt that can support high weights

- Angled PVC cleats for maximum stability of your passenger car, SUV & light truck tires on the conveyor

- Control box at both ends of the tire conveyor — on, off, reverse & emergency stop

- Requires no maintenance with its sealed precision ball bearing

- Reliable and smooth operation for gentle conveying

- A large place to place products to be conveyed

- All customary sizes can be conveyed

- Smooth conveying due to frequency-controlled drives

- Centre drive for forward and return conveying of each conveyor possible

- Damage is prevented

Less risk of accidents due to an enclosed plastic surface - Easy-to-clean surface

Add Ons

- Bag preparation systems to level or flatten bags

- Automatic product changeovers

- Quick-connect power and control cabling for faster installation in your facility

- Automatic slip/top sheet dispenser

- Exit conveyor

- Leak, weight, and metal detection systems coupled with a rejection conveyor to remove non-compliant bags

- Servomotor or pneumatic-powered gripper for automatic product width adjustment

- Integration with concurrent stretch wrapping machines and third-party suppliers (labelers, printers, etc.)

Safety Features

- Sheet dispensers are available to help stabilize loads

- Elevating lifts available to match existing infeed or discharge

- Expanded pallet dispenser capacity up to 25 pallets or multiple dispensers

- Ability to create taller loads to maximize the shipment truck space

Revolutionary • Intelligent • Future-Ready

Our Conveyor Machines, Systems & Solutions

Pallet Handling Solutions

Increase your operation’s throughput with our pallet-handling conveyors, ideal for moving large and heavy products. Alligator Automations designs systems that improve safety and cost-effectiveness, reducing heavy lifting and streamlining processes in manufacturing and distribution centers. Collaborate with our engineers to integrate the ideal conveyor solution, whether as a standalone system or part of a fully automated material handling setup.

Product Handling for Cases, Bags, and Crates

Our Case/Bag/Crate conveyors efficiently move product cases within warehouses. Configured to meet specific spatial, throughput, and operational needs, these systems effectively manage carton movement, sorting, and staging. Features include belt conveyors for moving items up or down, accumulation conveyors to prevent bottlenecks and live roller conveyors for navigating curves and merges. Our solutions ensure smooth operations and handle various product types and sizes effectively.

Trusted by Industry Leaders Worldwide

Meet Our Valued Clients

Get In Touch

Have questions or need a customized automation solution? We’re here to help! Reach out to us for expert guidance, tailored solutions, and seamless support. Whether it’s inquiries, collaborations, or service requests, our team is ready to assist you. Contact us via phone, email, or visit our office—let’s drive efficiency and innovation together!