IMPORATANCE OF PALLETIZING

Palletizer machines have become an essential part of automation, replacing human error and injury in manufacturing with efficiency and speed. In addition to such benefits, palletizers can handle environments that would otherwise be injurious to workers. Instead of requiring the hire of more laborers to do this work, many companies have adopted palletizers into their workplace environments in order to get the job done more quickly, effectively and safely.

WHAT WE DO

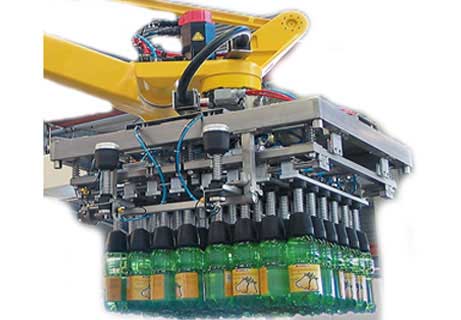

Alligator offers two types of automated palletizing. The first type, robotic palletizing, is becoming more popular and more affordable. Likewise traditional, or conventional, palletizers are also widely used including: bag palletizers, case palletizers, and gantry crane palletizers.Our engineers are experts in automating palletizing operations through both robotic and conventional palletizer system. In regards to robotic expertise, we’re an official partner with Fuji and we are skilled with ABB and Fanuc as well. We can provide turnkey solutions, enabling your project to be implemented with a single source of responsibility. This eliminates finger pointing and ensures smoother project implementation.

ADVANTAGES OF PALLETIZERS

- Stacks better, more accurate quality load than manual labor.

- Replaces costs of manual labor – less workmen’s compensation claims.

- Error reduction and increased production speeds.

- Decrease in product damage and shipping costs.

Alligator Automation specializes in the design and manufacturing

of robotic automation solutions. Our robotic palletizing

systems, bulk and case solutions, and machine tending equipment

have improved the efficiency of plastics, consumer goods, food,

and pharmaceutical facilities around the country.

We offer 4 primary robot models. Each model brings its own

unique qualities and benefits to the ever-changing market place.

From the low cost EC-61 that uses less energy than a common hair

dryer to the high speed EC-201 robot capable of palletizing well

over 20 bags per minute.

TOUCH SCREEN CONTROL

There are many advantages associated with our control system. Years of research and testing contributed to the development of our touch screen control package. We have listed some of the advantages that accompany each Fuji Robot model.

- Real time I/O monitoring

- Inventory monitoring that corresponds with specific recipes

- Onboard error history log

- Onboard diagnostics designed to identify errors instantaneously

- Onboard automatic lubrication schedule system

- 400 programmable memory recipes

- Pre-programmed pallet patterns imbedded in the touch screen customized to meet your specifications

TECHNICAL SPECIFICATION

| Fuji ACE Model | EC-101 | EC-151 | EC-171HS / HD | EC-201HS / HD | EC-201W | |

|---|---|---|---|---|---|---|

| Type of Motion | Multi-Articulated | |||||

| Action Mode | Cylindrical | |||||

| Load Capacity (Including End Effector) | 300KG(353lbs) | 100Kg (220lbs) | 80kg (175lbs) /130kg (280lbs) | 70kg (150lbs) /200kg (440lbs) | 320kg (700 lbs) | |

| Palletizing Capacity (cycles / hour) | 1150 | 1200 | 1500 / 1000 | 1800 / 1600 | 600 | |

| Operating Area | 4 axis | |||||

| Degree of freedom | Z axis (vertical) | 2300mm (90.5") | 2400 mm (94.75") | 2300 mm (90.5") | ||

| R axis (longitudinal) | 1500mm (59") | 1600 mm (63.12") | 1500 mm (59") | |||

| Theta axis (rotation) | 330° | |||||

| Alpha axis (wrist) | 330° | |||||

| Repeatability | + 0.5mm | |||||

| Memory | 120-400 programming locations available | |||||

| Teaching method | Teaching playback / Teaching Support | |||||

| Power Requirements | (200 / 220V, 3 phase, 50 / 60 Hz) | |||||

| Power Consumption (Without PeripheralEquipment Load) | 2.5 Kva / 6.5 amps | 4 Kva / 10.5 amps | 6.5 Kva / 17 amps | 7 Kva / 18.4 amps | ||

| Robot Weight (Without End Effector) | 700 kg (1544 lbs) | 750 Kg (1654 lbs) | 1150 Kg (2536 lbs) | |||

| Pneumatic Consumption | *5.7 SCFM @ 70 psi (.5MPa) | |||||

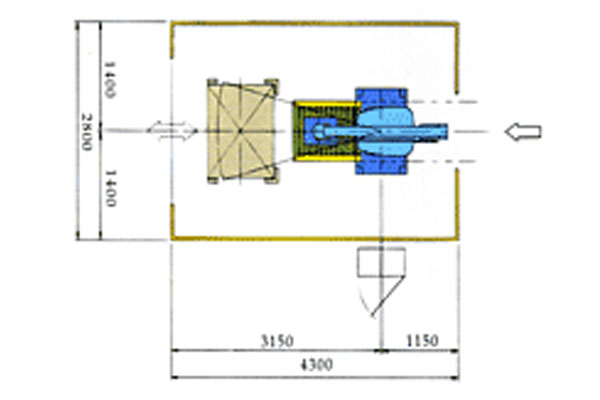

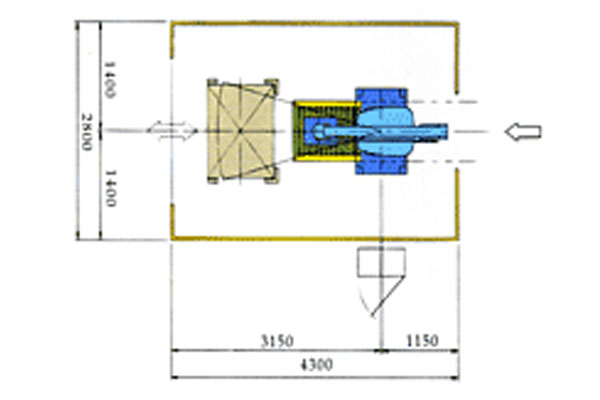

LAYOUT OPTIONS FOR THE PALLETIZER

There are many layout options that are available to match your exact specifications. Since we offer a high speed robot, we have the luxury to provide additional options while maintaining an aggressive capacity rate. The below depicts a small sample of the most common layouts.

i)

The product flows below the robot body. This compact layout provides minimum space usage and works well in narrow spaces.

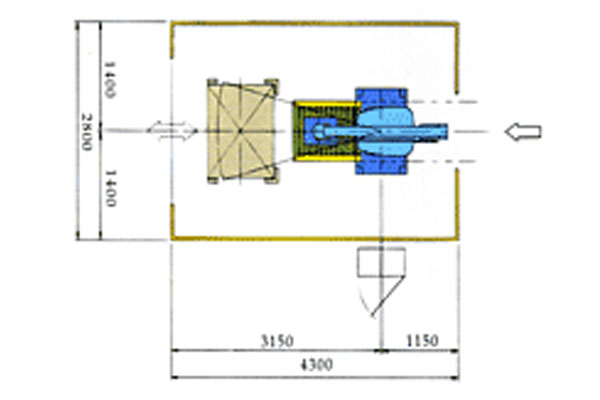

ii)

The product is palletized on two pallet locations. This design allows three pallets to be stacked on the floor on each side. This will minimize changeover time.

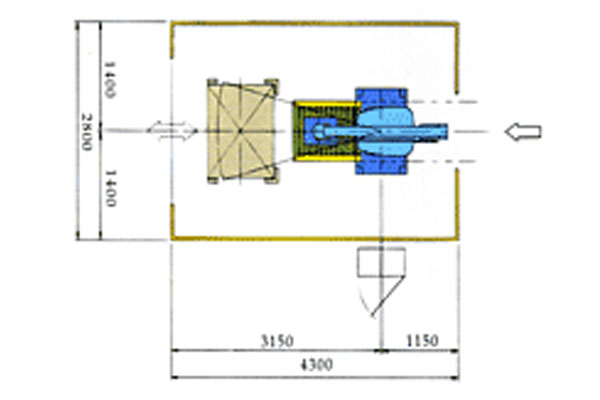

iii)

For high-speed applications, we decrease the pallet removal time by using a pallet conveyor to automatically transfer pallets while maintaining nonstop production.

iv)

One pallet magazine delivers empty pallets automatically onto two individual stacking lines simultaneously.